Nitrogen gas plays a critical role in processing, storing, packaging, and transporting products in the Food and Beverage industry. The inert gas is used to remove oxygen and moisture during food processing to prevent spoilage and prolong shelf life. It is also used to aerate food and drink products such as chocolate, beer, and coffee.

Markets within the food processing industry that commonly use nitrogen gas include:

- Fresh produce

- Coffee

- Edible oils

- Snack food

- Wine

- Dairy

On-site nitrogen generators ensure that a constant supply of high-purity gas is available on demand. They are safer, more affordable, and more time-efficient than traditional cylinders. Learn more about nitrogen generators for food and beverage, their applications, and the benefits they can provide for your application.

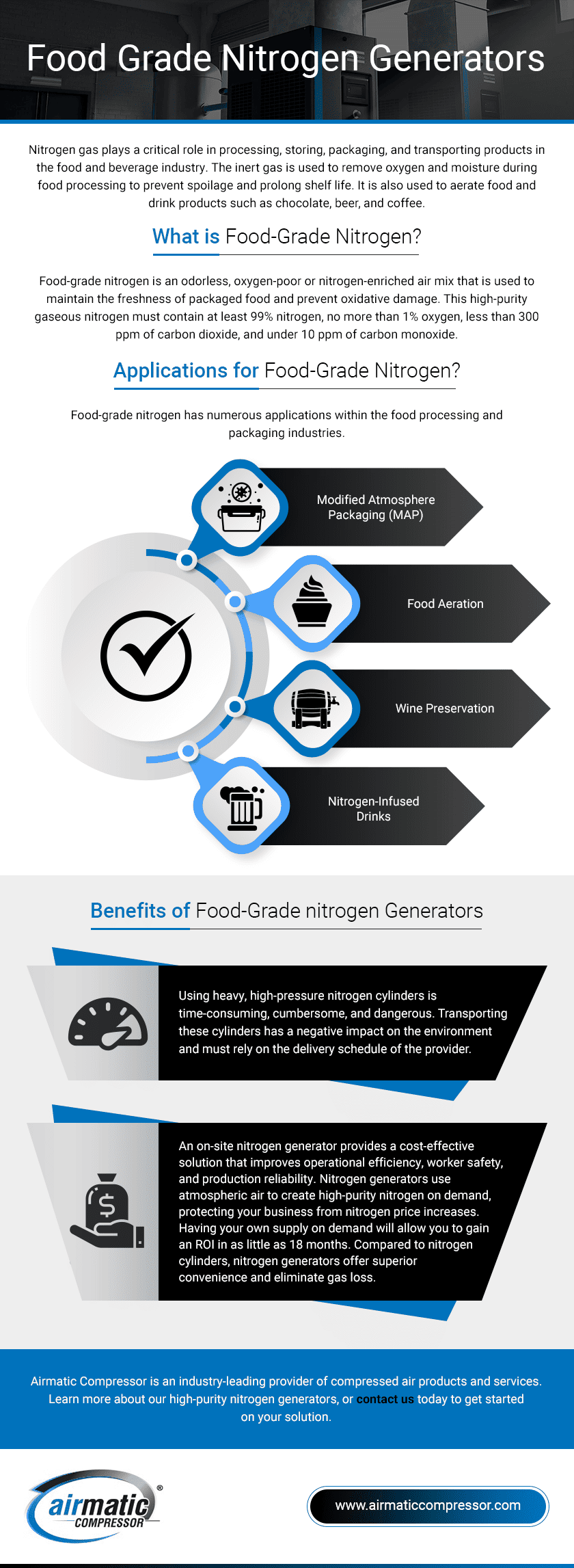

What Is Food-Grade Nitrogen?

Food-grade nitrogen is an odorless, oxygen-poor or nitrogen-enriched air mix that is used to maintain the freshness of packaged food and prevent oxidative damage. This high-purity gaseous nitrogen must contain at least 99% nitrogen, no more than 1% oxygen, less than 300 ppm of carbon dioxide, and under 10 ppm of carbon monoxide.

Applications for Food-Grade Nitrogen

Food-grade nitrogen has numerous applications within the food processing and packaging industries.

Modified Atmosphere Packaging (MAP)

Food begins deteriorating as soon as it is picked or processed for packaging. MAP modifies the atmosphere inside food packaging by using nitrogen to push oxygen out. Also known as gas flushing, protective atmosphere packaging, or reduced oxygen packaging, MAP significantly slows the growth of microorganisms and the rate of oxidation so that consumers receive fresh products.

Food Aeration

Food aeration is the injection of air into a food product to make it fluffy, whipped, foamy, or pumpable. Milkshakes, whipped cream, bread, cakes, popcorn, ice cream, carbonated drinks, and breakfast cereals are a few examples of aerated foods. In food aeration, the air must be clean and dry, or the oxygen present in the air will accelerate bacterial growth in the food and reduce its shelf life. Using food-grade nitrogen instead of compressed air avoids these challenges.

Wine Preservation

Once exposed to oxygen, wine oxidates quickly. Oxidation is the reason a bottle of wine will turn sour or get a vinegar-like flavor a few days after it has been opened. Nitrogen is commonly used in these two processes to keep wine fresh:

- Sparging: In this process, nitrogen is added to wine in the form of very small bubbles, which removes dissolved oxygen. This improves the taste and shelf life of the wine. Nitrogen gas sparging also improves the efficiency of the wine-making process by removing volatile contaminants.

- Nitrogen flushing: After fermentation and sparging, wine is stored in tanks or barrels. It is often transferred between storage vessels several times to prevent the buildup of sediment. Hoses and pumps used to transfer the wine are flushed with nitrogen to prevent oxygen exposure. Nitrogen flushing is used in the receiving vessel for the same purpose.

Nitrogen-Infused Drinks

Nitrogen is integrated into the brewing processes of beer, coffee, and other drinks due to its favorable effect on flavor and texture. Applying pressurized nitrogen to coffee and beer gives them a smoother, thicker texture and a foamy top. Compared to using carbon dioxide, nitrogen can achieve a frothier drink with smoother flavor and consistency.

Nitrogen for food packaging and processing is also used for controlled atmosphere storage, blanketing, grain fumigation, food freezing, and chilling.

Benefits of Nitrogen Generators

Using heavy, high-pressure nitrogen cylinders is time-consuming, cumbersome, and dangerous. Transporting these cylinders has a negative impact on the environment and must rely on the delivery schedule of the provider.

An on-site nitrogen generator provides a cost-effective solution that improves operational efficiency, worker safety, and production reliability. Nitrogen generators use atmospheric air to create high-purity nitrogen on demand, protecting your business from nitrogen price increases. Having your own supply on demand will allow you to gain an ROI in just 18 months. Compared to nitrogen cylinders, nitrogen generators offer superior convenience and eliminate gas loss.

Learn More About Nitrogen Generators for Food and Beverage

Food-grade nitrogen generators are necessary equipment in any food processing or packaging operation. Used for modified atmosphere packaging, food aeration, wine preservation, and nitrogen-infused drinks, nitrogen helps prevent spoilage and prolong shelf life.

Airmatic Compressor is an industry-leading provider of compressed air products and services. Learn more about our high-purity nitrogen generators, or contact us today to get started on your solution.