Table of Contents

Click to View Section

News, Events, and Happenings

Letter From the President

Anticipating the needs of our customers and delivering unparalleled service and support is a pledge we make to our customers and is in our company DNA. Our founder, my father, Nestor Vowteras started Airmatic Compressor 45 years ago on this very rule.

Times have changed, technology and the speed of business have both hyper-actively evolved and advanced. As the need for business to be more competitive and productive have intensified and evolved, so has their service needs. As the pressure on them builds, so does our responsibility to them.

Our job is to take that pressure off our customers and give them their day back. Our customers have been speaking to us for 45 years and we have been listening. Our customers continue to teach us how we can be more intuitive to their needs. They have taught us how we need to change and evolve to support their needs and the great team of people we have at Airmatic Compressor has executed.

Over our 45-year history, we have been honored to be of service to thousands of people, customers ranging from all types of business, large and small.

As we continue to grow our business, we are excited to learn from our customers to help us become better and more responsive to their needs and take the worry of compressed air off their mind and give them their day back.

Best Regards,

William N. Vowteras

President

Airmatic Compressor Systems, Inc.

New Hire

We are pleased to announce a new member of the Airmatic Team, Miguel Rivera. Miguel has 10+ years’ experience within the HVAC industry and is a highly motivated individual with a passion for providing excellent service to our customers. Miguel’s role will be to manage and expand our parts and mechanical business as an inside service coordinator. Please join me in welcoming Miguel to the Airmatic Compressor team!

We are pleased to announce a new member of the Airmatic Team, Miguel Rivera. Miguel has 10+ years’ experience within the HVAC industry and is a highly motivated individual with a passion for providing excellent service to our customers. Miguel’s role will be to manage and expand our parts and mechanical business as an inside service coordinator. Please join me in welcoming Miguel to the Airmatic Compressor team!

New Shop Online

Airmatic Compressor now has the ability for you to shop for your air compressor online. Our new shop online e-commerce page allows you to not only shop for new equipment but also compare equipment, request quotes, monthly promotions, and much more. Airmatic is also offering free standard freight shipment and free startup of your equipment with every online order. Just another way Airmatic is trying to make things easier for you to get the information or product you need when you need it and continuing to be your trusted source for compressed air products. Check out it out for yourself: Shop Online Catalog

Airmatic Launches Dedicated Vacuum Department

Vacuum, the invisible force, is indispensable in industrial production facilities around the world. When an industrial application requires a clean environment or pressure below atmospheric levels, a steady supply of vacuum is needed.

The use of vacuum is prevalent in many different industries, including food production, paper manufacturing, pharmaceutical and biomedical research and production, as well as many other general industrial uses.

While its importance in the manufacturing process cannot be argued, the understanding of its science is not altogether understood. There are no codes that govern the installation of a centralized or even point-of-use vacuum system, and very little available training for contractors, suppliers, and end-users. Like compressed air, vacuum is frequently misapplied, and the resulting system becomes unreliable, unstable, and grossly inefficient.

For the last 45 years, Airmatic Compressor Systems has been dedicated to helping our clients operate their businesses more productively with lower operating costs. To help our customers achieve these goals, Airmatic has formally launched the dedicated vacuum department, led by Associate Director Jeremy Garfield.

Jeremy brings over two decades of experience in the compressed air, whole building efficiency and controls industry, and will work together with Airmatic’s field sales and service teams to help our customer optimize new and existing vacuum systems.

From Jeremy:

For years Airmatic’s clients have benefitted from our compressed air expertise, and I look forward to helping to enhance the performance of their vacuum systems. Both Atlas Copco and Edwards offer industry-leading industrial and scientific vacuum systems, with a focus on reliability and efficiency, which lead to cost savings for our customers. Partnering with these impressive companies will allow us to effectively execute our plan for our clients which includes:

- Measuring and analyzing existing systems for productivity and efficiency opportunities

- Assisting in the design of optimized vacuum systems for new construction, renovation and expansions

- Leveraging utility incentive programs to minimize the first costs of efficiency projects

Providing world-class maintenance and reactive service, with available vacuum rentals at key flow and vacuum ranges.

Vendor Spotlight – EnergAir Control Systems

EnergAir has been providing control systems globally for over 30 years. Part of CMC, based in Belgium, EnergAir specializes in the design and installation of control and management systems for compressed air generation and vacuum installations. From basic turnkey control systems to comprehensive sequencing and master controls, Energair provides energy-saving solutions and complete systems in Pharmaceutical, Food & Beverage, PET Bottling, Automotive, Aggregate Processing and many other industries. Connecting and controlling multiple manufacturer’s equipment can be a challenge, but not so for Energair. Should your plant’s equipment be new, old, and made up of several manufacturers, adaptive devices ensure that all equipment can be brought together under a central controller.

Recently, with the push for equipment connection with the Internet of Things (Iot), EnergAir launched its cloud-based air compressor monitoring, performance, and control solution that provides real-time data, analytics, and insights at the push of a button.

The service known as Airmatics™ (not affiliated with Airmatic Compressor Systems) was developed to meet the requirements of Industry 4.0. Airmatics™ takes air compressor monitoring, performance, and control into the 21st century by providing 360° real time performance tracking of businesses’ air compressors – from anywhere in the world.

For a Demo of how the system works, follow the link below and take it for a test drive.

www.aircloud.airmatics.net/en/auth

Use Login: ‘airmatics’ and password ‘airmatics’.

Customer Success Stories

Successful Sale Against a Strong Competitor

Larry Emmolo, Systems Specialist

After receiving a phone from a potential new customer to upgrade their aging compressor, I was excited to put together a competitive high-performance air system. I was particularly motivated having lost a smaller compressor opportunity a few months back.

The customer had a 20+ year old 75 HP Gardner Denver compressor in his system supplying air to half the facility along with an older 25 HP GD unit that would occasionally come on during peak demand. Suddenly the GD 75 HP was wiped out with a bad air-end…it’s time had come.

Instead of simply throwing out an equipment list and pricing, I asked the customer to tell me the (3) three most important aspects of this job. His answer was delivery, pricing, and ease of installation.

Understanding how his system was operating, I recommended we upsize the compressor to a 100HP unit and eliminate the need for the other 25 HP GD to come on during peak demands.

Other than providing a competitive price with a quick delivery, the clincher that won the job was twofold: 1) The ease of mechanical installation with the hot air discharge off the top of the Atlas Copco Model GA75 unit made duct work connection easy and required less installation labor, 2) The existing 150 AMP service was all that was needed for our in stock GA75 – 100 HP offering. But the competitor’s 125 HP unit that was in stock need a 200 AMP service, which meant a significant electrical installation cost.

At the end of the day, we won the order and saved the customer thousands in both capital equipment and installation costs.

Compressed Air Application Advice and Tools

Technical Project of the Month

Oh, the things we’ve found

Bill Goerke, System Specialist

In last month’s issue of the Airmatic’s SmartAir Newsletter we made the case for compressed air system base-loading and how important it is to take those vital signs of your compressed air system by tracking compressor activity and pressure stability. So, here’s an example of the benefits when taking the pulse of an air system.

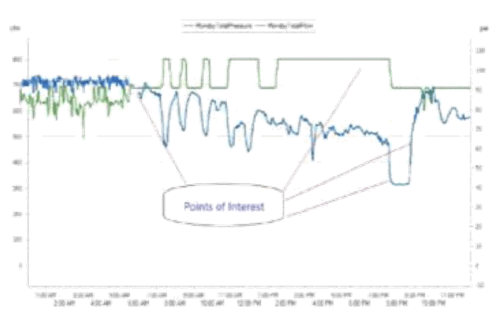

This customer has a (3) three-compressor system, with the air being dried by a heatless desiccant dryer…that’s all well and good, but see the chart below indicating performance problems.

We find the compressors are running full out to keep up, but there was something…some process happening in the plant that was causing pressure to bottom out at 40 psi. We spoke with personnel at the plant level, and they advised us that there were no real large air events; like a blowoff or a relief valve normally occurring.

Our initial thought was to add compressed air storage to the system…something to absorb the anomaly.

While walking the floor, searching for a place to house the proposed tank…lo and behold we find this…

…a 660-gallon receiver tank that was put into place, but never piped in….whoops!

The Mechanical Team at Airmatic Compressor made short work of the installation, got the tank online, and we took some readings…

What we got was a 30 psi improvement, a smooth-running system, and a customer that was relieved that their CapEx expenditure can go to improving air quality with the purchase of a new dryer, instead of another air compressor.

Many times, a large improvement does not involve an even larger equipment purchase.

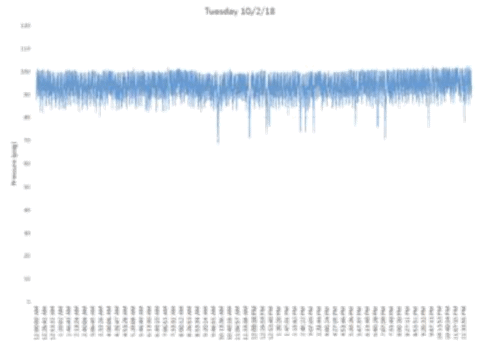

Benefits of Data Logging: The Importance of Periodic Air System Auditing, 10 Questions to Ask Yourself

David Van’t Slot, System Specialist

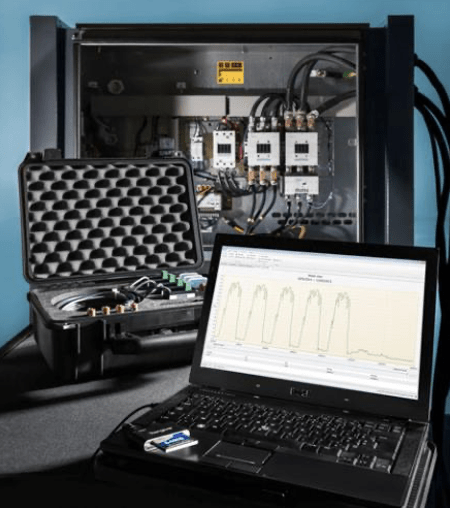

First of all, what is an M-box compressed air audit?? The expert team at Airmatic Compressor will hook up special data collection loggers to your compressor and receiver. These specialized loggers will collect and record amp draw and pressure level data for a week. That data is delivered to our trained engineer that will evaluate the data and produce an informative report that details your compressed air usage/ pressures 24 hours per day for the week. As a Plant, Production or Maintenance Manager, here are 10 questions that you should be asking yourself periodically to evaluate if an M-box could benefit the way you manage your plant compressed air system.

First of all, what is an M-box compressed air audit?? The expert team at Airmatic Compressor will hook up special data collection loggers to your compressor and receiver. These specialized loggers will collect and record amp draw and pressure level data for a week. That data is delivered to our trained engineer that will evaluate the data and produce an informative report that details your compressed air usage/ pressures 24 hours per day for the week. As a Plant, Production or Maintenance Manager, here are 10 questions that you should be asking yourself periodically to evaluate if an M-box could benefit the way you manage your plant compressed air system.

- Are you managing your compressed air system or just reacting to issues?

- Does your plant have sufficient back-up for your compressor system?

- Does unreliable air pressure/quality cause you to ruin raw material or product?

- Does your plant have enough excess compressed air to add new production equipment?

- Are there excessive leaks in your plant? It may not be your people whistling to pass the day…

- What is the energy cost to run your compressor system and are there energy saving upgrades available?

- Are there new technologies that can save energy and keep the compressed air quality at the optimal levels in your plant?

- Does your production team complain about the compressed air pressure or quality??

- Do you have enough storage/receiver tanks in the plant and do you have an outdated piping system that could cause pressure issues at certain parts of the plant?

- M-Box audit every six months? Wouldn’t you feel better knowing that your compressed air system is delivering everything that you expect and wouldn’t you like to know if there have been changes that need to be addressed before production is adversely effected?

If you are asking yourself any of the following questions–you should strongly consider calling your Airmatic Compressor Systems Specialist to schedule an M-box Audit.

The results will help you manage your compressed air system and not simply react to problems when it may be too late.

Tools of the Trade: Rule of Thumb Compressor Sizing for Horsepower Requirements

Rob Smith, System Specialist

We’ll start with the demand requirement and work our way back. What will the production equipment consume? This would be measured as CFM (Cubic Feet per Minute) and PSI (Pressure). As an example, if the machinery consumes 100 cfm @ 100 psi, the rule of thumb horsepower required for a screw technology compressor would be ~25, or about a 4:1 ratio of CFM/HP.

We’ll start with the demand requirement and work our way back. What will the production equipment consume? This would be measured as CFM (Cubic Feet per Minute) and PSI (Pressure). As an example, if the machinery consumes 100 cfm @ 100 psi, the rule of thumb horsepower required for a screw technology compressor would be ~25, or about a 4:1 ratio of CFM/HP.

As a comparison for reciprocating piston technology compressors, the ratio is 3.5:1, CFM/ HP. So, for this application we would need a 30 HP compressor. These calculations are based on a 100 PSI system, if the pressure requirement is higher, then less air will be delivered…or more horsepower required.

Keep in mind that there are many variables that come into play when selecting an air compressor for a new application.

Some manufacturers are more efficient than others, hotter working environments produce less air, the length of piping and the number of bends add to the pressure requirement to overcome and deliver air to the production equipment requiring more horsepower, and many others.

At the end of the day it’s always wise to have a qualified System Specialist look over your requirements and assist in selecting the best equipment for your application.

Service Event of the Month

Quick competent repairs with cost avoidance is a winning combo

William De Luca, Director of Technical Services

Receiving emergency breakdown calls happen all the time in the compressed air service business, but how a service organization reacts to a customer in their time of real need, can for sure determine the future of the relationship.

Receiving emergency breakdown calls happen all the time in the compressed air service business, but how a service organization reacts to a customer in their time of real need, can for sure determine the future of the relationship.

In many instances, just a timely response is the beginning of the customer expectations, and an expeditious competent repair at a fair price, would round out their top priorities. At Airmatic, beyond these top customer priorities, we also look to go the extra mile and assist customers with potential cost savings support as well.

A leading pharmaceutical company called us late one morning with an emergency breakdown on their oil-free air compressor that supports a critical area of their production. The downed unit was for a dedicated manufacturing process that had no backup machine, and they did not have a central piping network where they could utilize compressed air from another process within the plant. Simply put, they were dead in the water, and time was of the essence to avoid the hefty cost of lost production.

Our competent Field Service Technician quickly determined that the compressor had a cooling fan motor failure, and a shorted-out controller, but neither part was in immediate stock.

We needed to properly repair the machine, and with the parts not immediately available, the customer was inquiring about a rental compressor so they could be back up running first thing the next morning.

We could have easily supplied the customer with a rental package, but we went the extra mile in another direction to get them up and running asap in the most cost-effective manner. Our Service Team went ahead and cannibalized very near upcoming repair order for the same controller, and had the fan delivered next day early AM service.

Besides providing the path to quick uptime with a competent repair, we also assisted the customer greatly with a cost avoidance scenario for not having to endure the costs of a rental machine. Needless to say, the customer with thrilled across the board, and for the Service Dept. at Airmatic, this was just another day doing our best to provide exceptional service and value add to our customers!

After Market at its Best

Cleaning your air compressor

Craig Verga, Director of Aftermarket

Cleaning your air compressor is a basic preventative maintenance function that just about anyone can do. It is also a critical preventative maintenance function that can define how long your air compressor lasts. Consider the following facts:

- Air compressors constantly draws in air which it compresses for process output and which it also uses to cool internal components. It is an essence a big vacuum pulling all the dust and dirt in its environment.

- The capacity (amount of compressed air output) is directly related to the amount of air drawn in through the inlet air filter. A clogged inlet air filter

- In an oil injected screw compressor, the inlet air and the oil mix in the compression element. The result is that what is in the air, is in the oil.

- If there are abrasives in the oil such as fine dusts from stone or metals, they will eventually reach the bearings inside the compression element.

This contamination will cause premature failure.

- Significant amounts of dust and dirt entering the air compressor cabinet also build up on the outside of the air cooled oil cooler. The short term result of this condition is elevated oil temperature which will lead to nuisance shutdowns. The long term effect is oil varnishing inside the oil circuit. This causes consistent overheating which will require significant effort to remove. If not removed, it will cause premature failure.

- Significant amounts of dust and dirt entering the air compressor cabinet also build up on the outside of the air cooled after cooler. This results in elevated package discharge temperatures. This effects compressed air dryer performance, sending harmful moisture to sensitive downstream equipment.

- If you operate a variable speed drive air compressor, dust and dirt build up cause overheating in the motor inverter. This can cause both nuisance shutdowns and premature failure. The inverter is one of more expensive components on the air compressor, along with the compression element mentioned earlier.

Cleaning your air compressor is a simple task, that doesn’t necessarily require an experienced technician. Basic safety rules such as locking and tagging all sources of electrical and mechanical energy prior to beginning are of course necessary. Supplies needed can be as basic as a compressed air hose and rubber tipped air blowgun. If pressure washing is a preferred method, special consideration for electrical components needs to be taken.

October Sales Specials

Atlas Copco Promo

For the month of October, Airmatic Compressor will be offering 10% off on select Atlas Copco G and GX range of rotary screw air compressors!

For the month of October, Airmatic Compressor will be offering 10% off on select Atlas Copco G and GX range of rotary screw air compressors!

Plus, we are providing a no-charge startup service to make sure your machine is registered, warranted, and up and running smoothly.

Contact Airmatic Compressor today to take advantage of this special offer.

Click Here: Promotional Shop Online Catalog