Table of Contents

Click to View Section

News, Events and Happenings

New Hire

Katrina Vasta is our new Aftermarket Specialist. As the newest member of aftermarket team, her role is to help our service team to align closer with our customer’s needs and elevate the overall customer experience. Katrina’s previous experience was with an industrial manufacturer serving the railroad industry, so she understands the importance of critical infrastructure and uptime. She is looking forward to reaching out and working with all new and existing customer accounts. Welcome aboard Katrina!

Katrina Vasta is our new Aftermarket Specialist. As the newest member of aftermarket team, her role is to help our service team to align closer with our customer’s needs and elevate the overall customer experience. Katrina’s previous experience was with an industrial manufacturer serving the railroad industry, so she understands the importance of critical infrastructure and uptime. She is looking forward to reaching out and working with all new and existing customer accounts. Welcome aboard Katrina!

New Product

New Product

Here’s another home run from Atlas Copco. The newly introduced Cerades ™ range of desiccant dryers incorporates a new way of efficiently removing airborne water. The structured channel desiccant coated blocks significantly reduce pressure drop resulting in substantial energy savings. With no desiccant beads, maintenance costs are lower and no post filter is necessary to remove bead dust getting downstream.

Zeks Price Changes

Effective July 1, 2020: All Zeks products experienced an average price increase of 4.5%. Existing valid quotes that were issued prior to the price increase will honor the previous pricing. New and expired quotes that include Zeks products will reflect the price increase. Contact Airmatic Compressor for the latest pricing on Zeks products.

Customer Success Stories

Successful Equipment Placement

Robert Smith, System Specialist Success Story # 782

A local paper manufacture was having issues with their plant’s compressed air system losing system pressure periodically during the day. The site inspection found they were using air amplifiers (high velocity, low pressure) to remove scrap end pieces of paper from the conveyers. The venturi amplifier being used in the plant has a compressed air requirement of 350 cfm @ 100 psi, which created a very inefficient compressed air demand and ultimately starved other plant operations.

A local paper manufacture was having issues with their plant’s compressed air system losing system pressure periodically during the day. The site inspection found they were using air amplifiers (high velocity, low pressure) to remove scrap end pieces of paper from the conveyers. The venturi amplifier being used in the plant has a compressed air requirement of 350 cfm @ 100 psi, which created a very inefficient compressed air demand and ultimately starved other plant operations.

Our solution utilizes a 10” venturi air amplifier operating at a lower pressure, so a separate dedicated high-volume blower was sized accordingly. Based on the flow requirements and position of the new air amplifier, a 20 horsepower variable speed blower was used. With the variable speed blower, the customer was able to fine tune the flow for the different ribbons and paper being discarded. We were able to save the customer not only 45 horsepower of compressed air with an annual power savings of $21,000 but also the original issue of pressure drop in the plant has been corrected because the compressor demand was lowered.

Customer Interview

We believe that we have the best service technicians in the business, and our customers agree! When asked about the service provided by an Airmatic Service Technician, a local Pharmaceutical Manufacturer gave this response: “John Czernikowski did an excellent job. He looked at our equipment and gave a thorough analysis of our situation. We asked him to sit in on a quick meeting so that others on our wider team could ask their own questions and he was able to provide answers to all of them. Because of that, I would say in addition to his technical field expertise, he also has excellent communication skills.”

Compressed Air Application Advice and Tools

Technical Project Of The Month

Frank Asbaty, System Specialist

Nitrogen(N2) is mainly found in the atmosphere, where it accounts for 78% by volume of the air we breath. How do we take advantage of the Nitrogen in the air we breath that is all around us?

Nitrogen(N2) is mainly found in the atmosphere, where it accounts for 78% by volume of the air we breath. How do we take advantage of the Nitrogen in the air we breath that is all around us?

A Nitrogen generation system separates N2 molecules from oxygen and other minority gases and leaves nothing but highly purified(95%-99.999%), highly pressurized(if needed) N2 to use for various, specialized applications such as: Food packaging, Laser cutting and metal processing, Blanketing, Electronics soldering, Fire Retardant.

A recent application had a customer in the fire-retardant industry needing more Nitrogen than their current system could produce. Specifically, they needed to produce and fill twenty four (24) 80 liters bottles with a purity level of 99.9% at 5000 psi. The produce and fill process time must occur after normal business hours, overnight, before the next demand event. The current solution combines purchasing pre-charged bottles from 3rd party as well as utilizing a small in-house N2 generator. This rather inefficient process not only costs around $150K/ year, but includes safety concerns handling the bottles of N2 delivered on-site as well as the logistics of coordinating the purchase, delivery, and removal each month.

After meeting with the customer and uncovering specific needs and goals, we were able to provide a full turn-key, skid-mounted system solution that is able to generate enough N2 at their desired purity level of 99.9% at 5000 psi to fill their (24) 80 L bottles in less than 12 hours. The total system includes an oil-injected screw air compressor, the Nitrogen generator, a refrigerated dryer, a robust high pressure booster pump, high pressure air receivers, filtration, pressure and flow gauges, and most importantly a highly trained technical service and support staff at Airmatic to ensure proper functionality and efficiency from this system.

This solution allows the customer to use the generated N2 all day during their fire-retardant training classes without a hiccup. They can then turn on the N2 generator at the end of their day, let it produce N2 all night, and when they come back in the morning the bottles are filled and ready to go for another packed day of training classes.

For the right application, an N2 generation system can solve multiple problems a customer has with their existing system including, but not limited to, decreased operating costs, safer operation, turn-key, set it and forget it operation, very quiet, and low maintenance.

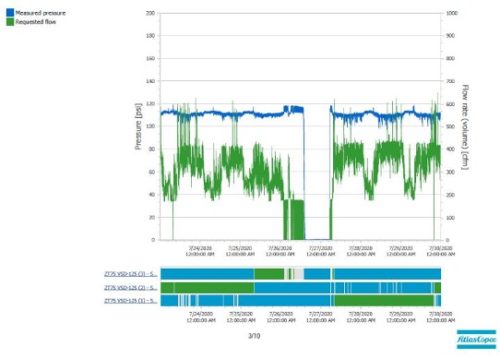

The Benefits of Data Logging

David Van’t Slot, System Specialist

To M-box or not to M-box. That is the question.

To M-box or not to M-box. That is the question.

Hint: M-box is a compressed air system audit.

Recently, one of my customers said to me: “Some production equipment is shutting down on low pressure—CAN YOU HELP?!” I assured him, with our in-house Engineer and state of the art compressed air audit tool (M-Box data logging), we can get to the root of the problem, fix it, and save energy/cost going forward.

We set up a time to tour the plant and identify the problem areas dealing with their two compressors ( 1-50HP VSD, 1-60HP VSD). The compressed air system is designed for 100% redundancy and historically either compressor would handle the plant. So, I explained how the audit tool will monitor the compressors for a week, tracking plant pressure and amp draw (Horsepower) 24/7. Once the compressor performance is logged and reviewed by our engineer a full report including graphics and charts will be presented to discuss the findings.

Our customer loved the idea and said “Where do I sign?”… After running the compressed air system outfitted with the loggers for about 10 days, we identified several areas of improvement. The report showed that 50% of the time both compressors were running, and at one point one of the compressors shut down and the plant pressure plummeted from 125 Psi to 80 psi causing the production low pressure alarm. This was due to the inability of one compressor not being able to handle plant air demand. In addition, if either of the compressors go down, the plant could not run full production causing major problems. Based on the findings we proposed a 3rd compressor which would add full system redundancy, as well as reducing energy costs by ~ $4700 per year. The customer was impressed with the report stating it was clear, concise and hit all the correct points. Together we presented it to his boss, the CEO. After our review the project was “greenlighted” as a new compressor project for the 3rd quarter 2020.

What useful information could the Airmatic Audit Program discover about your compressed air system? It may reduce risk and save energy costs for your plant!

Tools of the Trade

Larry Emmolo, System Specialist

Rule of Thumb – Calculating Make up Flow when Pressure Drops

Here’s a quick and simple rule-of-thumb on how to figure out the additional CFM needed to get the required operating pressure back to where it needs to be once the volume of air being used is more than the compressor can deliver.

As a real-life example, I recently worked with a customer who was operating a portable diesel air compressor (185 CFM) to sandblast headstones / monuments. The compressor must hold 120 PSI for the best production rate, but when using one blast gun pressure dropped to 110 PSI and with two guns operating, pressure was down to 90 PSI.

Here is the formula I use to estimate how much more CFM needs to be added to the system to get back to the higher production rate of 120 PSI.

Existing Capacity x (Desired Pressure/Existing Pressure) So, in the first scenario operating just one sand blasting gun, an additional 16 CFM is needed to get the pressure from 110 PSI (existing pressure) back up to the 120 PSI (Desired Pressure)

185 CFM x (120 PSI/110 PSI) = 201 CFM

201 total CFM is needed minus the 185 existing capacity = 16 CFM

Therefore we need to add 16 CFM to the existing 185 CFM to get us from 110 PSI back up to 120 PSI.

Applying the same math for operating both sandblasting guns where the pressure drops down to 90 PSI, gives us the following:

185 CFM x 120 PSI/90PSI = 246 CFM

246 total CFM is needed minus the existing 185 existing capacity = 61 CFM

So, 61 CFM added to his existing 185 CFM, or 246 total CFM, will handle both guns in use at the same time. The customer will be operating at the maximum productive pressure of 120 PSI.

Managing Emergency Calls

William De Luca, Director of Technical Service

“The formula for success at Airmatic: Marketing + Critical Service Dept. response = Satisfied Customer and a new compressor sale!”

Our Service Department received a panic call one late afternoon in the middle of April, right at the height of the COVID-19 pandemic, which was a very difficult period of time with support resources scarce for many businesses out there.

This customer is a leading metal fabrication company in northern NJ that counts on compressed air to keep their operations running, so restoring production asap was paramount for them. The customer’s machine had gone down on a drive motor failure, and they had no back-up unit. Obviously with no way to keep production going, this was a very urgent situation and thus time was of the essence.

The customer was being serviced by another provider and they called them desperately for assistance AS THEY ALSO NEEDED a rental compressor to get their plant back up and running while their in-house compressor could have its motor repaired. Unfortunately, the existing provider was unable to offer any form of assistance to return the plant to operation, so they had to go on a search for someone who could help.

The customer took to the Web to search for someone who could save the day, and as a result of a strong marketing presence, they easily found Airmatic! Even receiving the emergency call late in the day, our Service Department sprang into action to lend immediate assistance to the customer.

Airmatic has a full fleet of rental compressors, and had the exact size that the customer required. If a rental compressor is too small it won’t be able to support the plant load, and if it’s too large, they would not have adequate power to run the machine, so having the appropriate size is a very critical element. Our Service Department was in constant communication able to significantly jockey around the scheduling in order to accommodate the request. The plan consisted of having the rental compressor delivered 1st thing in the morning, and simultaneously our Service Technician would be onsite as well to hook up the machine. The result was in about 1.5hrs the customer’s plant was back up and running!

The customer was so impressed with the response and support he received from our Service Department that he wanted to look into purchasing a new machine from Airmatic. The rental was only supposed to be onsite to cover the duration of the motor repair, but that plan was abandoned and they elected to get a new compressor.

Our Compressor Sales System Specialist made an immediate visit to the customer to confirm all their requirements and propose an appropriate value-add solution, in which they quickly elected to proceed with the purchase. The rental continued to run their facility flawlessly until their new machine arrived, which was an Atlas Copco 40hp Variable Speed Drive compressor with an integrated refrigerated dryer, model GA30VSDFF.

The customer is very happy with their new machine, and to them we saved the day and their operations, but to the Service Dept. at Airmatic, this was just another day doing our best to assist our customers!

After Market at its Best

Finding the Optimal Preventative Maintenance Plan

Craig Verga, Director of Aftermarket Sales

In the modern industrial plant, there are many mission critical systems that keep products rolling out the door. Compressed air systems, nitrogen systems, vacuum systems, and chilled water systems are just a few. While most plant managers know the benefits to preventative maintenance in their facilities, there are tools that can be used to better understand whether the current preventative maintenance plan is right for your plant. For example, an analysis of the ratio of dollars spent on maintenance versus repair of these systems can be key to optimizing uptime while keeping an eye towards control. There are really two ways this can be accomplished:

In the modern industrial plant, there are many mission critical systems that keep products rolling out the door. Compressed air systems, nitrogen systems, vacuum systems, and chilled water systems are just a few. While most plant managers know the benefits to preventative maintenance in their facilities, there are tools that can be used to better understand whether the current preventative maintenance plan is right for your plant. For example, an analysis of the ratio of dollars spent on maintenance versus repair of these systems can be key to optimizing uptime while keeping an eye towards control. There are really two ways this can be accomplished:

- Ask your service provider to quantify the amounts spent on each individual system

- Look into your purchasing system to review the amounts on each system

Once these values are established, you’ll know for example whether 75% of every dollar spent is on maintenance and 25% is spent on repairs. Or maybe the ratio is more like 50% and 50%. But this is only the first step.

The next step is on evaluating your redundancy in that particular system. For example, if you run a 150HP air compressor system, and your back up is a 100HP air compressor, you most likely do not have full redundancy. The final step in the process to begin the analysis of understanding the cost of down time. I’d also say you should look at the cost associated with limited output, like in the example I used above. If you can only produce 66% output (100HP/150HP = .66), how does that affect profitability? Now you are armed with the information to make important decisions. But what’s the right course?

Airmatic Compressor recently helped a local Bergen County, NJ manufacturer with a similar analysis. It was found that five years prior, the ratio of maintenance to repair was 80% / 20%. This particular customer has full redundancy in their systems as well. However over the years, maintenance/repair ratio slipped more towards the 50% / 50% scenario. This migration was caused by shrinking maintenance budgets. But less maintenance caused more frequent compressed air system shut downs. Despite their redundancy, even the slightest outage had major financial ramifications due to ruined product. This also caused the backup systems to operate more frequently, and once dormant systems now had increased wear and tear. That also increases maintenance needs. The high cost snowball effect begins…

After identifying this ratio and understanding the full effects, a decision was quickly made to shift budget dollars back towards maintenance. The simple payback was obvious. By shifting the dollars spent from reactive to proactive,and by taking maintenance events from unplanned events to planned events they achieved the following results:

- Back to meeting production schedules

- Reducing overall lifecycle cost of their system

- Increased profitability

Contact Airmatic Compressor today if you’d like similar financial analysis or would like to evaluate the true lifecycle cost of a mission critical system in your plant.

August Sales Specials

August Sales Specials

Preventative Maintenance Sale

For the month of August 2020, Airmatic Compressor is offering 15% off first-time Preventative Maintenance agreements. By regularly performing preventative maintenance, you minimize the risk of high production costs due to poor performance and breakdowns.

For additional information, contact Airmatic Compressor and mention code “SMARTAIR820” to take advantage of this special offer.

Atlas Copco Promo

Atlas Copco Promo

For the month of August 2020, receive 10% off on Atlas Copco GA Series 10, 15, 20, 25, 30, 35, 40 & 50 HP VSD+ Rotary Screw compressors. Contact Airmatic Compressor to take advantage of this special offer!