For any type of air compressor, regular preventative maintenance is essential for keeping your equipment operating at its best. A properly maintained compressor will deliver a longer service life without impaired performance or costly breakdowns.

Airmatic Compressor can ensure your production processes are always running optimally, with expert air compressor preventative maintenance services designed to reduce your overall operating costs.

Learn more about the different types of preventative maintenance tasks, proper scheduling, and useful tips for keeping your equipment running at optimal capacity.

Preventative Maintenance Tasks

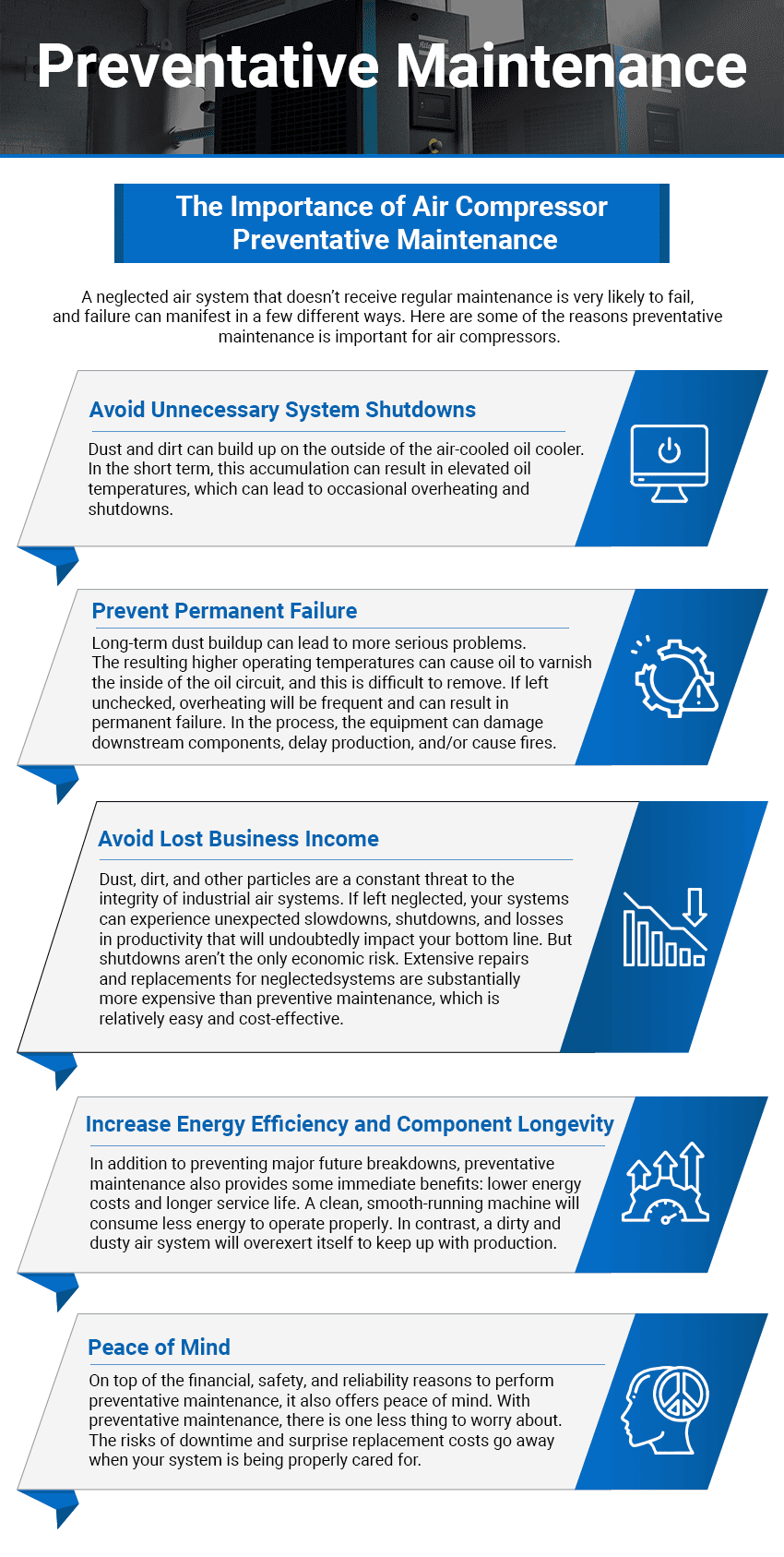

A poorly maintained air compressor costs money both directly and indirectly. Not only can it lead to overloaded filters and blockages that increase energy costs, but it also increases system wear and causes breakdowns that require emergency repairs. Preventative maintenance helps to avoid these issues by keeping your equipment at peak operating conditions.

Some of the most important preventative maintenance tasks include:

- Draining excess fluids from the air compressor and air receiver tank: Perform this task daily if you’re not using an automatic drain valve.

- Changing the air filter regularly: The frequency will depend on your equipment usage and operating environment.

- Changing the oil and oil filter at recommended intervals: Check these frequently and change them when you see signs of excessive loading. Typical replacement intervals range between every 4,000 and 8,000 hours.

- Inspect hoses and connectors: These are susceptible to high levels of wear that can cause leaks, putting strain on the pump motor. Look for splits, cracks, and other types of damage.

- Check and tighten fasteners and electrical connections: Vibrations can cause nuts, bolts, and electrical connections to loosen over time, leading to short circuits or failure. Inspect all of the wires, screws, nuts, and bolts and keep them snug but avoid over-tightening.

- Test safety mechanisms: Ensure the electrical and mechanical safety mechanisms are functioning correctly.

- Inspect belts: In compressors with belt drive systems, look for wear and verify that the belts have proper tension levels.

- Clean external components: Dust and dirt can hinder air compressor performance when it accumulates on certain external components. Regularly clean the compressor’s fan grate, cooling fins, air intake vents, and other housing air pathways.

Maintenance Schedule

While each air compressor model is different, a typical recommended maintenance schedule involves various daily, weekly, monthly, quarterly, and yearly tasks:

- Daily: After use, drain condensate from the air tank, check for obvious oil leaks, and inspect air hoses for cracks or damage.

- Weekly: Check the oil level and replenish as needed.

- Monthly: Check and tighten all fasteners and electrical connections. Clean external components and air pathways, inspect belts for wear, and replace components if necessary.

- Semi-annually: Change the oil, oil filter, and air intake filters. Check belt tension and test safety mechanisms.

- Yearly: Change the oil and air separator element and clean the fuel tank.

Additional Maintenance Tips

In addition to ensuring your equipment receives regular preventative care, there are a few other general maintenance tips that can extend the life of your machine.

Keep the Workspace Clean

Clean the air compressor itself as well as the environment around it. Ensuring the working environment is free from dirt, sawdust, or other types of debris will reduce the frequency of maintenance tasks and can even extend the lifespan of compressor components. Any type of dust in your environment can build up along air filters and pathways, shortening the lifespan of your filters.

Schedule Preventative Maintenance for Your Air Compressor

Air compressor preventive maintenance is essential for keeping your equipment operating reliably and preventing costly unscheduled downtime. You can ensure your machine receives the best possible care with preventative maintenance services from Airmatic Compressor. Our knowledgeable team provides on-site repairs and services to customers throughout New Jersey. To learn more, review our maintenance, repair, and extended warranty programs, or contact us with any questions.